Components:

-

Wood - Poplar and other types of Wood

-

Liquid PU resin as sidewall

-

Stainless Steel Inserts

-

Sintered Polyethylene Base

-

Sublimated PBT Topsheet

-

Steel Edges

-

Fiberglass

-

Carbon

-

Kevlar

-

Epoxy resin

-

Hardener

The Snowboard

Sandwich

Made with:

-

CAD Software

-

CNC Router

-

Graphic Software

-

Sublimation Press

-

Drill Press

-

Clamps

-

Snowboard Press

-

Belt Sander

-

Edge Sharpeners

-

Other tools and techniques

Different species of wood are glued together and then the core planks are made with heavy industrial machinery.

The whole process starts with choosing the right wood for the cores. We partner with industry leaders for responsible and sustainable wood sourcing.

Core drying reduces the moisture content of the wood before its further processing.

Prior the actual manufacturing, every shape is designed on CAD software.

Drawings are being imported in post-processing software that controls the machines.

Graphic designs are being printed and then sublimated deep into the materials. Sublimation is a printing process that allows for vibrant exceptionally durable graphics both on the base and the topsheet.

All components are heated and pressed together in a mold that defines the final geometry of the board.

After the board comes out of the press we still have a lot of cleanup work to be done before it really starts looking like a snowboard.

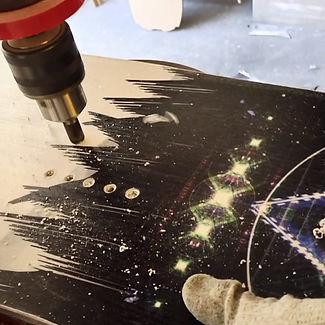

Excess material is carefully ground away, and the edge is exposed. The inserts are drilled out. Next step is the final cleanup and edge tuning.

Edge sharpening, waxing and polishing - in every single process, we use hands with skills, meaning your new snowboard is carefully finished by a real human.

Balkan Snowboards

Factory Store

Great! Now you know a lot about snowboard manufacturing. There is plenty of work not mentioned here. You can always ask us for more details on this topic, if you find it interesting.

Go on and choose what you want to see next: